The world of 3D printing has been raised to a greater extent in the last few decades. Right from basic household accessories to viable personal protective equipment, there are a lot of things that Selective Laser Sintering (SLS) services have served as. 3D printing Services have eased up everything and have made it easier for people to know about different products in detail through their 3D models. But still, there are some concepts that even the best artists struggle on for elaborating the glorious world of Selective laser sintering.

Simple photos and sketches can provide us a good idea about the concept but there are still some concepts that fail to explain through photos and sketches completely. A 3D model is a prototype that you can touch on hold and feel. 3D models are quite important for businesses. The 3D models were already there in the marketplace for ages but the only thing that differs them from the modern ones is that they were being made by hand. Whether it is the aerospace industry, medical industry, dental industry, or laser beam, 3D printing platform is being consistently used everywhere.

Creating such 3D models with hands is a hectic task and that is the same reason why related machines were introduced into the marketplace. 3D printing software has boosted up the manufacturing of prototypes. These printers not only ease up your tasks but are quite fast and cost-effective too. The guide is specially designed to introduce you to the exact functioning of a 3D printer.

What is 3D Printing?

Table of Contents

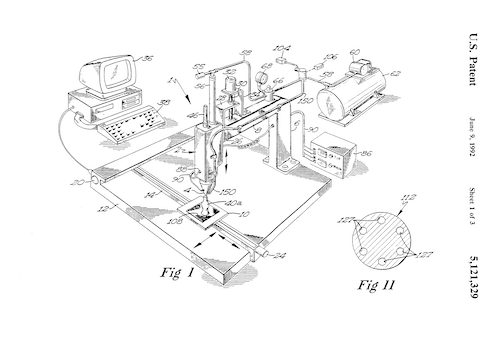

Before exploring the working process of a 3D printer, it gets quite important for a person to know what exactly it is. 3D Printing is an additive manufacturing process that is being used to design and construct three-dimensional solid objects. The 3D scan uses a computer-aided design that is also known as CAD for creating three-dimensional objects from digital files.

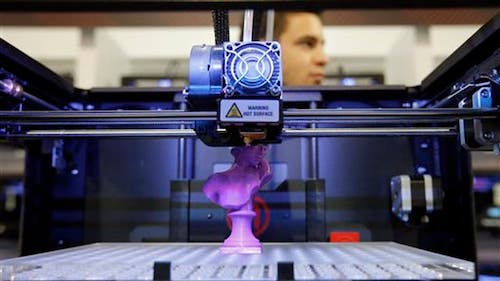

The process works on the layering method where successive layers of the materials are being laid down layer by layer until the final 3D print is being created. The entire process of 3D printing is being done by adding layers on each other and hence also known as additive manufacturing technologies. Users can easily see the thinly sliced layers in a fine cross-section of the object. The 3D printing process usually includes different types of layering materials such as plastics, composites, metal objects, or bio-materials. The best thing about 3D printing is that it can effectively create objects in different shapes, sizes, rigidity, and colors.

If you are willing to produce complex shapes using fewer materials, 3D printing can serve to be a great option for you. The introduction of 3D printing machines has eased up our lives to a greater extent. 3D printing platforms are currently serving as a major aspect of everyone’s lives. Right from packaging food-grade items to pharmaceutical industries, there is a wide range of possibilities for 3D prints.

The word 3D printing is not a newer one in the marketplace. Right from hand-made 3D prototypes to rapid 3D prototyping, it has to take a long way to go. The best thing about 3D printers is the extreme flexibility of printing. One can easily make use of plastics for printing rigid materials such as sunglasses and can also create flexible objects like phone cases or bike handles with the 3D printers effectively. You can even find some 3D printers in the market that can have the ability of printing with carbon fibers and metallic powders. These types of 3D printers are most commonly used in constructing strong industrial products.

Why are 3D printers important?

The introduction of 3D printers has put on a greater impact on everyone’s life. 3D printers are known for their extreme flexibility. They not only provide a wide range of opportunities to the users but also can be effectively used with a wide range of materials. The 3D printer includes a very simple and intuitive interface that makes access quite easier. You can print your preferred 3D print with these machines without making many efforts.

Adding more to it, the 3D printers are incredibly fast and accurate. They actually can serve to be a promising tool for future manduction. The majority of the 3D printers available in the market are designed to ensure rapid prototyping. Everyone wants to have a faster work speed and that’s why the demand for 3D printers has rapidly increased in the last few years. The majority of the companies all around the world have started using 3D printers for creating their prototypes in just a matter of a few minutes. 3D printers claim to be about 10 times faster and five times cheaper than normal R&D processes.

3D printing now has become a very important part of almost every industry. They not only just create the prototypes rapidly but also provide absolute finishing to them. Right from fixing the broken parts of the ventilators to print complete homes, from providing absolute learning sessions in schools to creating robotics pieces, 3D printing is now serving as a great help in every industry. The presence of features like adaptability and flexibility has made this technology a compulsion in every field.

How does a 3D Printer work?

The world of 3D printing is quite huge. This technology has become a game-changer option for every industry and that’s why its demand in the market has increased rapidly. The world of 3D printing is just like a science fiction movie, where 3D prints have emerged as superheroes who save everyone. 3D printing is part of the additive manufacturing technology that works on the same principle that traditional inkjet printers do. 3D printings work with the combination of three things. It requires a top of life software and powder materials for creating 3D prints, whereas precision tools are also quite necessary in the process of three-dimensional printing. Modeling and slicing software is generally used in 3D printing just to guide the 3D printer for creating each 3D print perfectly.

We are adding here a detailed guide that will lead you towards the absolute functioning of a 3D printer.

3D Modeling Software

The game of 3D printing starts with creating 3D modeling and to ensure it is successful one needs to have 3D modeling software. 3D printers usually work on manual instructions. You have to guide it on what actually to do for creating an absolute 3D printing. But doing that manually every time is not practical and that’s why 3D modeling software comes into existence.

You can make use of 3D printing for creating both simple and complex 3D prints. 3D modeling software is being designed to enable absolute precise designs quite conveniently. For example, if you are working in the industry of dentistry, you need to design and work on the teeth aligners that can precisely fit the individuals. Practically it is quite a hard thing to achieve but the absolute usage of 3D modeling software can make it a smooth run for you. 3D modeling software applications are also being widely used in the space industry for designing intricate parts of rocket ships.

Slicing the Model

Once you have successfully created your 3D model, the next thing you have to work on is slicing it. The 3D printer itself can’t conceptualize the concept of three dimensions and that’s why we need slicking software for slicing 3D models perfectly. The slicing software scans each layer of the 3D model precisely and commands the printer how to move in for recreating that layer perfectly. It’s only the slicing software that tells the 3D printers where a 3D model requires a fill and where it does. Fill is a quite important segment of every 3D printing process that provides internal lattices and columns to your 3D print and hence helps in maintaining its shape and strength. Slicing software perfectly slices the 3D models and then gives commands to the 3D printer for initiating the actual printing process.

3D Printing Process

The final game of 3D printing gets started up after the completion of the tasks being processed by 3D modeling software and the slicing software. 3D printers are just like a traditional inkjet printer with some additional features. If we talk about the simple and direct 3D printing process, the nozzle of the 3D printers moves back and forth which further dispenses a wax or plastic-like polymer in layer format. 3D printers rest in wait for some time until the previous layers get dried completely before adding the next ones. Hundred of 2D prints are being added upon each other with each layer and that further lead up one to the final three-dimensional objects.

What are the different filament options being used in 3D printing processes?

3D printers have the capabilities of working with a wide range of materials. 3D printing is the best way to recreate the absolute 3D model of objects with the best abilities. The most common filament options being used by the 3D printers are:

ABS

ABS is an acronym being used for Acrylonitrile butadiene styrene. It is a plastic material that can be easily shaped and resized for creating different objects. The best thing about ABS is that it is quite hard to break on.

Carbon Fiber Filaments

This type of filament option is most commonly used for creating strong and lightweight 3D prints. The carbon fiber filament is being designed by infusing the fragments of carbon fibers in a polymer base. One can easily use these filament options with different 3D printing materials such as PLA, ABS, PETG, nylon, and different others for creating more effective results.

Conductive Filaments

The conductive filaments are designed to create 3D print electrically conductive components. These filament options are very important for wearable technology and are being used with PLA or ABS materials for creating low-voltage electronic circuits, buttons, raspberry Pi cases and power connectors, etc.

Flexible Filaments

Being constructed from thermoplastic elastomers, this filament option is blendable and tough. The material is quite elastic and is being used for printing materials like bands of wristwatches and phone covers.

Metal Filament

Metal filaments are often being created from finely ground metals and polymer glue. Bronze, aluminum, copper, brass, stainless steel are one of the most commonly used metal filament options in the market. The best thing about metal filaments is that they provide the looks and the feel of real metal to the users.

Wood Filament

Wood filaments are usually being designed by combining a PLA-based material with absolutely fine ground wood powder. These filament options are used for printing wooden-looking objects.

How much time does it usually take to take absolute 3D prints?

The actual timing of the 3D printing process depends upon its complexity. One can easily make a 3D print of simpler materials such as a phone cover, box, or a ball mini chess, etc. in just a few hours, whereas it can take weeks or longer for creating complex 3D prints like a pedestal bridge, or a full-sized home. While going out for the 3D printing process, you need to consider the size, detail, and scope of the object you are working on.

Not every 3D printer available in the market works the same. Right from a simple inkjet printer to FDM printers, one can easily find a wide range of options there. There are some differences among all that also affect the printing process of the final 3D object. FDM printers i.e. Fused Deposition Modeling are one of the most common types of 3D printers. The best thing about these 3D printers is that they can be effectively used for prototyping plastic models quite fast.

If we talk about the speed of the 3D printers, printers featured with Stereolithography Technology i.e. SLA is supposed to provide fast prototyping with intricate details. These printer options usually use ultraviolet light for crafting 3D prints. DLP or Digital Light Processing printers are one of the oldest 3D printing formats available in the market today.

Costing of the 3D printers

The market is full of a wide range of 3D printer options. One can easily get a 3D printer for up to $200 whereas you may need to spend about $100,000 for getting the other. Features like size, specialty, and usage create a lot of differences between the different 3D printer options. The overall pricing of 3D printers has dropped to a greater extent in the last few years. It has become an important part of almost every industry. We will advise you to create a list of your preferences first, before heading towards the marketplace for the 3D printer. It will help you in getting the best option at affordable pricing. For more reliable results, going with the brand name is also beneficial.

Conclusion : How do 3D Printers Work

3D printing technology has become an integral part of different industries. A 3D printer not only helps you in getting absolute products at affordable pricing but it is a great way to understand the complexity of different things in a better way. It is a part of a wide range of applications such as mass customization, cloud-based additive manufacturing, rapid prototyping, research, food, agile tooling, and much more. Working on a 3D printer is never so easy until you have absolute knowledge of it. We have tried to add on here the different aspects of 3D printing along with its absolute functioning so that you can get an idea of how important technology is and how it has eased up things for us.