Have you ever explored the world of 3D printing?

If yes, you might be well aware of how vast it is. 3D printing offers users a vast range of possibilities. The best thing here is that one can efficiently use different types of filaments to access different features successfully.

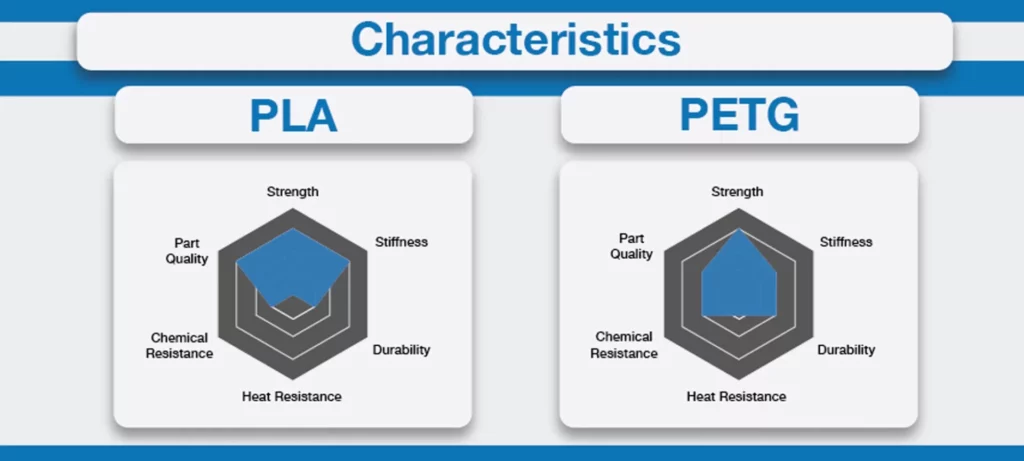

PETG and PLA both are the two most popular filament options for 3D printers that have set up different trends in the marketplace. If you’re feeling overwhelmed trying to decide between the perfect 3D print, don’t fret! We’ll make it a breeze for you with all the info needed. Prepare yourself – hilarity is guaranteed! We will provide you with a comparison between both filaments i.e. PETG Vs PLA and will discuss their applications as well.

What are PETG and PLA?

Table of Contents

PLA and PETG both are the filaments of the 3D printers that belong to the polyester group of plastics. Both of these 3D printing filaments are thermoplastics and that is the main reason both have gained huge popularity in the last few years. Both PLA and PETG tend to soften up at specific temperatures and solidify on cooling down. Not only are both filament options highly durable, but their quality remains consistent use after use!

PLA and PETG can be used in 3D printing. PLA is an acronym for Polylactic Acid. PETG stands for Polyethylene terephthalate glycol-modified. PLA is a polyester plastic filament that is good for beginners. PLA is designed to make 3D printing projects look good.

PETG does come up with different physical properties of ABS that ensure users have many easy prints conveniently. PETG type of filament is good to use when the project you are working on needs to be smooth and without mistakes.

See This: Delta 3D Printers Review

PLA vs PETG: Which is Better?

It is quite difficult to declare the best one among the two, without knowing about its detailed features. If 3D printing was a game of ‘Rock, Paper, Scissors’, PLA and PETG filaments would be like two similar-looking siblings that are really hard to tell apart. Both belong in the same family – polyester plastic – but what makes them different under the surface? If you don’t know what exactly are they, don’t miss to check out this detailed comparison we are going to provide you below:

The Final Printout

Despite having a lot of similarities, both PLA and PETG do have some unique features that create a lot of differences between the two. And the leading difference between the two is their final printout.

Physical Strength

If you are going to work on a project that you have to carry out at different places or you have a 3D module that can provide high-end durability, PETG filaments are the most preferable option. The physical strength of the PETG filament is quite higher than that of the PLA and that is the main reason why the majority of people opt for it rather than PLA.

Temperature Tolerance

The temperature tolerance of the PETG is also quite higher than that of the PLA filaments. It means that if you are going to work on a 3D project that requires high-end heating, PETG filament would be a great option to choose. If you’re looking to 3D print comfortably, PETG filaments can bring the heat to 75°C. On the other hand, PLA is more of a cool kid and works best under 55°C– don’t turn up the dial too far!

You can use different blends of PETG such as Arnite 3040 and Nexeo 3D for working on 3D projects with higher temperatures around 250°C.

PLA Vs PETG Filament: The Best Differences

Usage and Transparency

PETG is perfectly great to be used for outdoor purposes whereas PLA can’t withstand harsh weather conditions in any situation. If you are working with PLA filament and are willing to extract durable results from it, you have to paint your 3D printers and have to keep on protecting them from different elements. The transparency of the PETG filament is also quite easy to achieve.

Form Structure

PLA works as a great option for all those who are willing to produce complicated 3D prints. The best thing about PLA filament is that one can easily find a wide range of options providing absolute support for it to work on. You can easily smoothen up the surface of the PLA 3D print and can remove the support material as well to provide absolute 3D prints.

Color Matching

PETG filaments cause issues in exact color matching as well. One can easily make perfect color-matching 3D prints with the help of PLA without any issues.

Mimicking

PLA filaments are available in different material blends and that’s why it gets quite easier for you to mimic other materials efficiently. One can use different metal filaments for mimicking those particular metals and PolyWood to mimic wood filaments. PETG filaments don’t support mimicking.

Recycling

PETG and PLA may not naturally decompose, but they can still be re-purposed! Properly recycling your 3D printer filaments creates a continuous cycle of ecological sustainability. For example, when it comes to PETG you’ll need the help of some fancy technical equipment while it magically turns back into its original components once recycled – making it one heck of an environmentally friendly filament solution!

Also See: Is Resin Waterproof

PETG Vs PLA: Best Applications

Printing

There are a lot of differences between the final 3D printing of PETG filaments and PLA filaments. You should need to know about the different things especially when you are going to purchase a suitable 3D printer filament.

Bed Adhesion

The bed adhesion quality of PLA is much better than that of PETG filaments. The best thing about PLA filament is that one can easily ensure absolute 3D printing even without a heated bed. PLA wraps up very little and gets adhered to the bed perfectly at the same temperature without getting any issues.

The bed adhesion of the PETG filament is a bit complicated. One has to heat the bed around 50°C to 70°C for taking perfect 3D prints. Moreover, the PETG filaments also wrap up quite higher and need to heat up to a particular temperature for adhering to the bed.

Printing Temperature

The printing temperature for PLA filaments is a bit lesser than that of PETG filaments. The PLA prints are a bit cooler than that of the PETG filaments but much lowering in temperature can even tend to nozzle clogging issues in your 3D printers as well. Both PETG and PLA filaments can be used in blended formats as well.

Post Processing

If you like painting, use PLA filament for 3D printing. It’s easy to work with acrylics and offers great adhesion. Don’t expect regular glue to work the same as super glue. You need to be more careful with regular glue, like finding the right starting point when working with polyester. Get superglue and an accelerator combo pack. These are the key ingredients you need for unbreakable bonds!

Quality of the Prints

PLA filaments are well known for providing more high-quality prints than PETG filaments. The stringing and oozing issues are quite common in PETG filaments. If you are working on PETG filament and are looking forward to reducing such issues, we would prefer you to take 3D printouts at a bit lower temperatures. Make sure not to lower the nozzle temperature too much as it can easily cause nozzle clogging issues in your 3D printers.

Also Read: Voron 3D Printer Reviews

PETG Filament Vs PLA: Comparison

Nozzle Gap

Working on the PLA filament is much easier than that on the PETG filaments. If you’re used to PLA filament, but you’re trying PETG filament for the first time, make sure the nozzle gap is a bit bigger. This will help prevent too much bed adhesion and improve your 3D prints. You can adjust the height of the Z-axis for working on certain projects with PETG filaments.

Filament Density

The PETG filament is a bit dense than the PLA filament. The common density value for PLA is 1.24 g/cm3 while the common density value for PETG is 1.27 g/cm3.

Overall Support

The overall support for both PETG and PLA filaments is too good. Both work efficiently great with a majority of materials and provide high-end 3D prints at different situations and heating points. When it comes to distance settings, one needs to keep the overall distance between the model and the support a bit higher in the case of PETG filaments than that PLA filaments.

Filament Changing

The filament-changing process is also a bit more complicated with PETG filaments than that with PLA filaments. For example, if you were previously working on the PETG filament and are now going to use PLA filament, you need to keep the nozzle temperature applicable for the PETG filaments only. You can only lower the temperature to work efficiently on the PLA filament until the PLA filament starts extruding out. This process is extremely easy to avoid the chances of clogging the nozzle of your 3D printers.

Pricing and Color options

The other main difference between the PETG and PLA filaments is their pricing. Both PETG and PLA filaments do come up with a unique set of features that provides ultimate projects without any issues. Both PETG and PLA filaments come up in a wide range of color options. If you are preferring transparency over colors, PETG filament would be a great option choose in but if you are willing to have a project with desirable colors, PLA filament would be a great option to choose. PLA filaments are known as the most popular and slightly cheaper than PETG filaments.

Applications

PLA and PETG filaments offer various properties that make them suitable for many tasks. These materials have made their way into a variety of projects, proving to be invaluable components in the world of 3D printing. If you are going to work on a project with early-stage prototyping, or you are going to create showcase models and quick features, PLA filament would be a great option to choose. The PLA filament is not perfect to be used outdoors. Exposure to water can lead them to decay very quickly. Users can easily improve the durability of the PLA projects using paints on them.

If you want to work on industrial projects, you need to use stronger filament options like PETG. This will help you make something that will last a long time. PETG is also resistant to water, heat, UV light, and other things that could damage it. This makes it a safe material for food projects. It can even keep your food safe for outdoor applications as well.

Conclusion: PLA Vs PETG

I hope you guys have well understood the basic and main differences between PLA and PETG filaments. Both PLA and PETG filaments are polyester filaments but they do comprise some unique set of features that makes them the best as their own. Both of the filaments are being used in a wide range of applications.

It is quite difficult to say which one is better than the other. I would rather say here, usage depends upon one’s preferences and the features included in the filament options. If a project requires long-term, robust quality – PETG’s your friend! But if you’re looking to get creative with vibrant colors and silky textures? Reach for PLA. Both will serve you well in the kitchen too… but when it comes time to tackle an industrial challenge: PETG is really where it’s at; not only can this master of materials stand up tall against heat, UV light, and solvents –it’ll probably outshine them all.